Life Cycle Assessment (LCA) explained

Life Cycle Assessment (LCA) is taking centre stage in the sustainability world, but what exactly is it and why is it so important for your company?

In this blog, we demystify LCA by explaining what LCA is, how to conduct an LCA, why your company needs it and how automated LCA platforms like Root can transform your sustainability journey.

PUBLISHED: 28 July 2022

Updated: 14 November 2024

WRITTEN BY: Gijs de Mol and Charlie Walter

Table of contents

- What is Life Cycle Assessment (LCA)?

- Why are LCAs so important?

- LCA terminology explained

- What is a product life cycle?

- The different types of LCA

- LCA example: plastic vs. reusable bags

- How to conduct an LCA

- How to get started with LCA

- Challenges of traditional LCA and how LCA software helps

- Root’s approach to LCA

- How we can help

What is Life Cycle Assessment (LCA)?

LCA is a comprehensive input-output analysis where all environmental impacts of products and services are measured throughout their entire life cycle. This includes inputs (e.g. raw materials and energy) and outputs (e.g. waste and carbon emissions) at every life cycle stage from production to disposal.

LCAs provide the data and insights you need to measure, compare, and reduce the impact of the products you make, buy, use, and dispose of.

Beyond providing data, LCAs help you make informed decisions by revealing the environmental sustainability trade-offs of different choices, enabling you to reduce your environmental footprint effectively.

As mentioned, LCAs measure the environmental impacts of products and services. As Root focuses on helping product companies, this blog focuses on how LCAs are used for product companies.

LCA stands out from other sustainability measurement tools as it provides a holistic assessment of a product’s environmental impact. It goes beyond carbon emissions to assess a range of environmental metrics including water use, chemicals, resource depletion and waste.

This holistic approach helps avoid siloed thinking, for example ‘carbon tunnel vision,’ which is a term used to describe when companies only focus on carbon emissions of their products without understanding their product’s broader environmental impact, e.g. biodiversity and human health. LCAs stop siloed thinking as you have the full picture of your product’s environmental impact, enabling you to make smarter, more informed decisions.

Image source: Carbon Tunnel Vision based on graphic by Jan Konietzko

Why are LCAs so important?

In today’s sustainability landscape, your company needs more than just good intentions – you need robust company and product-level data to prove your sustainability credentials and show measurable progress on your commitments.

Let’s explore the key factors driving demand for LCA:

The importance of scope 3 in the race towards net zero

Increasingly, companies are realising that focusing on scope 1 and 2 emissions (aka emissions from your direct operations) is no longer enough to set and achieve net zero goals.

Think of scope 1 and 2 emissions as the tip of the iceberg. The bulk of emissions – and the most significant opportunities for reduction – lie beneath the surface with scope 3 emissions. Scope 3 is the emissions that occur throughout your value chain.

With scope 3 emissions often accounting for up to 90% of an organisation’s carbon footprint, understanding and reducing scope 3 is crucial to achieving meaningful reductions. As the saying goes, ‘you can’t manage what you can’t measure’ – LCA data provides the crucial company and product-level footprint carbon data that sustainability teams need to create and track progress on net zero targets.

Regulatory pressure

The regulatory landscape is evolving fast, becoming more demanding and increasingly focusing on scope 3 emissions and product-level data.

Compliance with regulations like the ESPR, CSRD, Digital Product Passports, Green Claims Directive and CSDDD isn’t optional, and the stakes are high. Businesses that do not comply risk fines, damaged reputations and loss of stakeholder trust.

Compliance teams can no longer rely on benchmarked data – they need detailed environmental data at the product level. LCAs provide the science-based, robust data these teams need to prepare for these regulations and future-proof their business.

Greenwashing and green claims

Gone are the days when companies could make vague green claims like ‘eco-friendly’ or ‘carbon neutral’ without providing evidence to back up these claims.

Did you know that 40% of green claims in Europe last year were unsubstantiated? With the introduction of regulations like the Green Claims Directive, marketing teams need product-level data to evidence green claims. LCAs are needed to provide reliable environmental data, empowering marketing teams to make credible green claims and confidently promote products while avoiding greenwashing risks.

The rise of ecodesign

With 80% of a product’s environmental impact being determined when designed, companies are beginning to prioritise sustainable innovation and adopt ecodesign to create more sustainable products.

Ecodesign is essential for meeting regulatory demands, driving innovation and reducing companies’ environmental footprint. LCA data empowers design teams to make more sustainable choices and use ecodesign to create more sustainable products. Companies are realising the necessity of having LCA data on entire product portfolios to guide product innovation and how important this is to reduce their overall environmental footprint.

For example, Root’s product-level footprints and scenario builder enable design teams to understand the environmental impact of design decisions, such as comparing the environmental impact of using organic versus conventional cotton on environmental metrics like biodiversity and carbon emissions. This data-driven approach helps design teams make smarter product design decisions without the guesswork.

Supply chain transparency

Regulators and stakeholders are increasingly shifting their focus from company operations to the sustainability performance of company value chains.

LCAs are essential to improving supply chain transparency. LCAs provide crucial data about the product’s entire life cycle, including vital information about suppliers’ environmental performance. This data is crucial for procurement teams as they can use LCA data to evaluate suppliers and make informed, data-driven decisions, such as partnering with suppliers with strong sustainability performance that helps achieve their sustainability goals. Ultimately, LCAs can improve the transparency and significantly reduce the environmental impact of supply chains.

The key takeaway? LCA is not just a tool but a catalyst for positive impact – empowering companies like yours to accelerate your sustainability journey and future-proof your business.

LCA terminology explained

Let’s face it – the LCA jargon can be overwhelming! Understanding these terms will help you navigate the world of LCA:

| LCA term | Definition |

|---|---|

| Critical review | An external review to ensure compliance with ISO standards (ISO 14044). |

| Functional unit | A reference measure is used for comparison, such as 1 kg of product or 100 units of service. |

| Hotspot analysis | Identifies areas in the product life cycle that contribute the most to environmental impacts. |

| Input | Any resource or material used during the product’s life cycle. |

| Interpretation | The step of the LCA process where the results are analysed to draw conclusions and identify areas for improvement. |

| Life Cycle Impact Assessment (LCIA) | The step of the LCA process where Life Cycle inventory data is converted into environmental impact using impact references (e.g. using the ecoinvent database). |

| Life Cycle Inventory (LCI) | The data collection step of an LCA process collects quantifiable data on inputs (materials, energy) and outputs (emissions, waste) for each stage of a product’s life cycle. |

| Product system | All activities and processes included in the system boundary contribute to the product’s functional unit. |

| Reference flow | The amount of product needed to fulfil the functional unit used to scale the LCA. |

| Screening LCA | A quick assessment to gain an overview of the environmental impacts of products and identify the key impact drivers using high-level assumptions. |

| System boundary | Defines the scope of the LCA, including which processes and stages are included. |

| Waste | Refers to materials discarded during the life cycle whether in production, use or disposal. |

What is a product life cycle?

Before diving into the LCA methodology, let’s first clarify what a product life cycle means.

According to ISO 14040, there are five stages to a product’s life cycle:

- Extraction and pre-processing of materials: Gathering the raw materials needed to produce a product. Key impacts include resource depletion, energy use and land degradation.

- Processing and manufacturing of products: Converting raw materials into finished products. This stage is often energy-intensive and generates waste.

- Distribution from suppliers and to consumers: Moving materials, semi-finished goods and final products across the supply chain. Key impacts include emissions from fuel use.

- Usage of products: The phase where consumers use the product.

- What happens after products have been used: The product’s end-of-life stage, whether it’s disposed of or recycled once used.

These steps are not set in stone, but it is wise always to use them as a starting point when considering a product’s life cycle.

The different types of LCA

There are four main types of LCA and each one serves a different purpose:

- Cradle to cradle: Focuses on designing products for recycling or reuse, creating a closed-loop system that minimises waste. Cradle-to-cradle assessments are the most comprehensive approach as they consider every stage of a product’s life and are suitable for companies embracing circular economy principles. This is the right LCA for you if you want to create products that can be reused or recycled endlessly.

- Cradle to grave: Evaluates a product’s entire life cycle from raw material extraction to disposal.

- Cradle to gate: Assesses a product’s environmental impacts until it leaves the factory (the gate). Businesses conduct cradle-to-gate LCAs to understand production impacts without considering how their products are used or disposed of after use.

- Gate to gate: Focuses on the environmental impact of their product’s production – without looking into upstream or downstream impacts.

The type of LCA you choose depends on your business goals, whether you’re looking for a full life cycle analysis or focusing on a specific life cycle stage like production.

LCA example: plastic vs. reusable bags

Let’s look at a real-world example of LCA in action: single-use plastic vs. reusable bag alternatives.

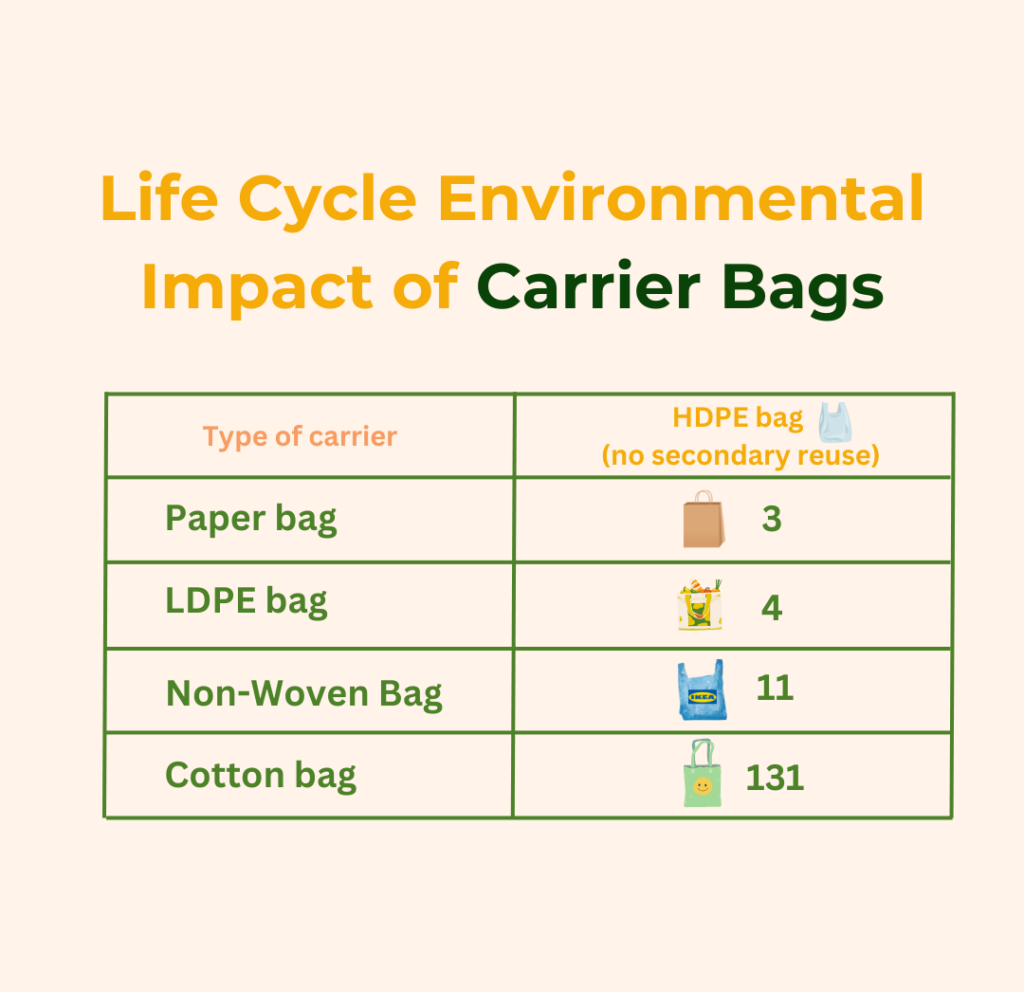

You might think switching to a paper or reusable cotton tote bag is automatically better for the environment, but it’s not that simple.

An LCA study comparing single-use plastic bags to reusable alternatives revealed that the number of times a bag is reused, not the material, is the crucial factor determining its overall sustainability.

Here’s what they found:

- HDPE single-use plastic bag: Low production impact but contributes to plastic pollution.

- Paper bags: Requires 3 uses to have a smaller environmental impact than a single-use plastic bag.

- LDPE plastic bags: Needs to be used 4 times to be more sustainable than a single-use plastic bag.

- Non-woven PP plastic bags (like Ikea bags): Requires 11 uses to be more sustainable than a single-use plastic bag.

- Cotton tote bags: Needs to be used 131 times to have a smaller footprint than a single-use plastic bag.

The results of this study were surprising to many as it challenged the assumption that anything ‘reusable’ must be better for the environment.

In this case, the impact was determined by the total number of times the bag was used, not the bag’s material. This study spotlights the importance of assessing the full life cycle of a product, not just the material when making design choices.

This study highlights the value of conducting LCAs to make informed, data-driven decisions around sustainability. Without detailed product-level data from LCAs, your company could make well-intentioned but misguided decisions that do not improve your products’ environmental footprint.

How to conduct an LCA

The ISO 14040 and 14044 standards outline four main steps when conducting an LCA:

- Goal and scope definition

- Inventory analysis

- Impact assessment

- Interpretation

In an ideal scenario, these four steps would follow one another in a linear process – in practice this rarely happens. Fortunately, with Root’s methodology, we have embedded these four steps into our platform, so you do not need to worry about these steps too much.

Let us explain each step:

Step 1: Goal and scope definition

In this step, you first determine which products or services you want to include in the LCA, aka what is in and out of scope. The fundamental question you need to answer is: which products do we want to include, and how many products will we assess in the LCA?

Once this is confirmed, you then define the goal and the intended application of the LCA and identify the target audience of the LCA. As a final step, you define the scope of the assessment (e.g. cradle-to-gate, cradle-to-grave) by determining the level of sophistication of the study, which relates to the goal of the LCA.

When partnering with Root we will handle this step for you. We always aim to assess your entire business, so we assess all your products throughout their entire life cycle, and our LCAs aim to reduce your environmental footprint.

Step 2: Inventory analysis

This is the data collection phase of the LCA, also known as the Life Cycle Inventory (LCI).

This involves collecting and organising all inputs and output data throughout your product’s life cycles, so gather data on everything that flows in and out of the system boundary. Organising the data collected is vital to ensure that the environmental impacts can be easily calculated and interpreted in the following steps.

Examples of inputs are the raw materials of products or the energy consumed in the factories, and examples of outputs are residual waste streams from factories or end-of-life treatments for products.

When working with Root, this step is simplified. We ask you to provide raw data from your management systems and upload it onto Root’s platform using our intuitive onboarding modules. We then organise the data for you so that we can easily convert it into actionable insights in the following steps.

Step 3: Impact assessment

Now that all data has been collected and organised, it is time to apply meaning to your data.

Within the ISO 14040 and 14044 standards, this step is better known as the Life Cycle Impact Assessment (LCIA), which includes a set of mandatory steps that are required for this step:

- First, you select impact categories to include in the LCA, aka which impacts you would like to measure, e.g. carbon, water, waste.

- Next, you classify the data in the LCI, assigning it to our defined impact categories.

- The two are combined to calculate the environmental impacts.

Luckily, nowadays these steps are standardised into comprehensive LCIA methods and LCI databases. At Root, we use the internationally recognised LCIA method ReCiPe and the LCI database ecoinvent, the world’s most commonly used combination for LCA.

Step 4: Interpretation

The final step of the assessment is the interpretation, but this doesn’t necessarily only have to happen at the end of the assessment. However, once all data is in place, the interpretation of the LCA is most accurate.

The aim of this step is to analyse the data and create conclusions, understand the study’s limitations and create recommendations so companies can use the LCA results to create a positive impact in their business.

On Root’s platform, the results of the LCA are displayed using our dynamic dashboards, allowing you to intuitively and easily interpret the LCA results with minimal LCA knowledge. Additionally, you can use our scenario builder to help you analyse alternative scenarios to identify ways to reduce your environmental footprint. We dive into Root’s approach to LCA in more detail later in the blog.

How to get started with LCA

Using LCAs to create a positive impact in your business does not need to be complex and overwhelming. Below are Root’s tips on how to start incorporating LCA into your business:

Start with a hotspot analysis

Begin with a hotspot analysis to identify high-impact products, suppliers, processes, etc that significantly contribute to your company’s environmental footprint. Focus your resources where they will make the most difference.

Embrace simplification and screening

Use simplified LCA methods for large projects, focusing on the key drivers of impact. Apply the 80/20 rule where 20% of factors drive 80% of your environmental footprint.

Develop a consistent methodology

Create a consistent, company-wide methodology for conducting LCAs. This will ensure all teams are aligned and working toward the same sustainability goals.

Focus on data quality over quantity

Start with the data you have, but aim to improve it over time by building stronger relationships with suppliers and improving your data collection processes. Identify the essential data needed for the critical impact drivers and focus on gathering data on these drivers first.

Integrate LCA insights into business decisions

Share the insights from your LCAs with C-suite and the key departments in your business using easy to understand, LCA jargon-free language. Make sure the results are accessible to those with little LCA knowledge. When sharing insights, focus on the actionable next steps created from the LCA results, such as redesigning a product or improving supply chain sustainability. This makes sure the LCA results create tangible outcomes, inform business decisions and create a positive impact in your business.

Challenges of traditional LCA and how LCA software helps

While LCA is a powerful tool, traditional LCA has several challenges. Below are the common critiques of traditional LCA and how automated LCA software like Root helps address them:

Not scaleable

Traditional LCAs are typically for one product and are often too time-consuming to be conducted on multiple products. Root solves this by automating the LCA process, enabling you to measure the impact of thousands of products across product portfolios at once, making LCA scalable and efficient.

Inefficient

Manual data collection is one of the biggest bottlenecks in conducting a traditional LCA. Root streamlines the data collection process by connecting directly to your company systems and using artificial intelligence and algorithms to organise your data and create actionable insights. This frees up your team’s time to focus on interpreting the results and taking action rather than being stuck in the intricacies of data collection.

Inaccessible

Traditional LCAs require specialised LCA expertise, making it difficult for non-experts to interpret and use the results. Root solves this by creating an intuitive platform that makes LCA results easy to understand for people with little LCA knowledge. As a result, LCA is no longer a niche topic limited to a few experts in your company. Instead, it becomes a company-wide initiative key departments like marketing, product design, procurement, and C-suite can engage with. By making LCAs accessible, automated LCA platforms like Root help create a company culture that embraces and celebrates sustainability.

Incomplete data

Traditional LCAs often face challenges with incomplete data, especially for scope 3 carbon emissions. Root addresses this by initially focusing on gathering data in the areas of your business that have the most significant impact. Root conducts a screening LCA to identify the critical impact drivers contributing to your company’s environmental footprints and focuses on gathering data where it matters most. We also use proxy data to fill data gaps, which helps create complete LCAs.

Root’s approach to LCA

At Root, we make measuring, reducing and communicating your environmental footprint simple.

Here’s how we do it in four simple steps:

Step 1: Upload data

First, upload your company and product data through our user-friendly onboarding modules.

- We guide you every step along the way to collect the right primary data for your environmental impact calculation.

- Collect and upload data once, reuse and combine it indefinitely.

- Behind the scenes, based on your data, we define your product life cycles at once.

To stop data gaps from hindering your ability to use LCAs to positively impact your business, if data gaps exist, we help you make informed assumptions and use proxy data to fill them.

We also conduct a screening LCA to pinpoint your biggest environmental impact drivers, allowing you to focus on collecting the 20% of data that drives 80% of your company’s environmental approach. Over time, we help you improve data quality. This strategic approach makes sure data gaps do not stop you from using LCAs to create a positive impact in your company.

Step 1: Upload data

First, upload your company and product data through our user-friendly onboarding modules.

- We guide you every step along the way to collect the right primary data for your environmental impact calculation.

- Collect and upload data once, reuse and combine it indefinitely.

- Behind the scenes, based on your data, we define your product life cycles at once.

To stop data gaps from hindering your ability to use LCAs to positively impact your business, if data gaps exist, we help you make informed assumptions and use proxy data to fill them.

We also conduct a screening LCA to pinpoint your biggest environmental impact drivers, allowing you to focus on collecting the 20% of data that drives 80% of your company’s environmental approach. Over time, we help you improve data quality. This strategic approach makes sure data gaps do not stop you from using LCAs to create a positive impact in your company.

Step 2: Measure impact

Understand your biggest emission drivers, identify hotspots and start acting now!

- Gain insight into each product’s environmental footprint, e.g. carbon emissions and water consumption.

- Zoom in per product, supplier, operational facility or customer.

- Learn more about the origin of your impact. Is it hidden in the materials of your products, mostly due to operational activities or transport or is it caused by the usage and end-of-life treatment of your products?

Step 2: Measure impact

Understand your biggest emission drivers, identify hotspots and start acting now!

- Gain insight into each product’s environmental footprint, e.g. carbon emissions and water consumption.

- Zoom in per product, supplier, operational facility or customer.

- Learn more about the origin of your impact. Is it hidden in the materials of your products, mostly due to operational activities or transport or is it caused by the usage and end-of-life treatment of your products?

Step 3: Analyse insights

Model alternative scenarios to discover the most effective reduction strategies for your company.

- Improve the material impact of your products by refusing, rethinking or replacing them with more sustainable alternatives.

- Reduce operational impacts by switching to renewable energy, improving efficiencies and minimising residual waste.

- Rethink supply chain partners and choose more sustainable alternative modes of transport.

- Improve the usage impact of your products by optimising energy efficiency, creating sharing platforms or adopting “product as-a-service” business models.

- Extend the lifespan of products and parts by offering reuse, repair refurbishment and remanufacturing services.

Step 3: Analyse insights

Model alternative scenarios to discover the most effective reduction strategies for your company.

- Improve the material impact of your products by refusing, rethinking or replacing them with more sustainable alternatives.

- Reduce operational impacts by switching to renewable energy, improving efficiencies and minimising residual waste.

- Rethink supply chain partners and choose more sustainable alternative modes of transport.

- Improve the usage impact of your products by optimising energy efficiency, creating sharing platforms or adopting “product as-a-service” business models.

- Extend the lifespan of products and parts by offering reuse, repair refurbishment and remanufacturing services.

Step 4: Optimise impact

Discover how reduction strategies impact your goals and start sharing your journey with the world.

- Use company and product-level data to create sustainability goals and monitor progress.

- Communicate your environmental impact journey with customers, employees and stakeholders through reports, blogs and websites.

- Ensure compliance with mandatory sustainability regulations, such as the CSRD and Green Claims Directive.

Ultimately, Root makes LCA simple and scaleable, turning LCA data into actionable insights that empower you to reduce your company’s environmental footprint and drive positive change across your business.

Step 4: Optimise impact

Discover how reduction strategies impact your goals and start sharing your journey with the world.

- Use company and product-level data to create sustainability goals and monitor progress.

- Communicate your environmental impact journey with customers, employees and stakeholders through reports, blogs and websites.

- Ensure compliance with mandatory sustainability regulations, such as the CSRD and Green Claims Directive.

Ultimately, Root makes LCA simple and scaleable, turning LCA data into actionable insights that empower you to reduce your company’s environmental footprint and drive positive change across your business.

How we can help

At Root, we aim to redefine the norm by making product footprints universal. Our platform conducts automated LCAs for entire product portfolios – helping businesses report effectively on regulations, avoid greenwashing and become industry leaders in sustainability.

Root creates comprehensive LCAs that help businesses accurately measure, reduce and communicate their company-wide and product-level footprints.Interested to learn more?

Get in touch with our team to discover how Root can help you achieve compliance and drive sustainable growth.